How to choose water treatment equipment? This real stuff tells you !hits [629] publish time :2020-08-06

In the previous article, we talked about the hazards of scale to ironing equipment, and the way to solve the problem of scale-configure

professional water treatment equipment. However, there are so many kinds of water treatment equipment on the market, how to choose?

Today, we brings you this real stuff, you will understand after reading it! According to the degree of water purification, water treatment

equipment can be basically divided into three types: water purification equipment, water soften equipment and pure water equipment.

Let's take a look at the difference between the three equipments.

The working principle of ordinary water purification equipment

A water purifier composed of a single PP cotton filter element, or a single activated carbon filter element or a combination of PP cotton

and activated carbon. After tap water enters the PP cotton filter element, only substances less than 0.1um and water molecules are allowed

to seep out from the membrane wall, and harmful substances greater than 0.1um are trapped in the membrane core to achieve a simple

purification effect.

The filtration accuracy of ordinary water purifiers is not high. It can only remove impurities in the water, such as rust, sand, bloodworms,

etc., but cannot completely remove scale. It belongs to primary filtration and generally does not have the washing function. Therefore,

the PP cotton filter element needs to be replaced frequently, according to the raw water The water quality needs to be replaced every

3-5 months.

2. Working principle of water softener

The water softener uses ion exchange technology to exchange the functional ions on the resin withthe calcium and magnesium ions

in the water to absorb excess calcium and magnesium ions in the water to achieve the purpose of removing scale (calcium carbonate

or magnesium carbonate).

The water softener can filter the calcium and magnesium ions in the water, the soft water will not produce scale, the water conductivity

is good, and the heating efficiency is high. It is necessary to replenish the industrial granular salt to the salt tank regularly, and the

maintenance cost is lower in the later period, which can completely solve the problem of clogging the boiler valves and pipelines due to

the generation of scale.

3. Working principle of pure water

The pure water equipment adopts RO membrane reverse osmosis water treatment technology. When tap water enters the RO membrane

tube, under the action of water pressure, the densely packed micropores on the membrane surface only allow water molecules to pass

through, and any other substances are trapped in the RO tube. It is discharged when the membrane is flushed.

The filtration rate of the reverse osmosis membrane can reach above 98.5%, and the filtration rate of bacteria, heavy metals and other

substances can reach 100%. Because calcium and magnesium are removed, it is also softened water, which is not easy to scale, but the

water production rate is low and produce a lot of waste water.

After knowing above, I believe we have a certain understanding of the types of water treatment equipment, and the advantages and

disadvantages of various types, we also summarized for everyone:

Water purification equipment: It is a primary filtering equipment with low cost. It can filter out rust and sedimentimpurities, but it cannot

filter harmful metals and other substances, and it will still produce scale.

Pure water equipment: high filtration accuracy, filtration rate up to 100%, but high waste water rate, and high initial installation cost and

later RO membrane replacement cost are higher, more suitable for areas with serious water pollution.

Water softener: can remove calcium, magnesium ions and other elements in the water, and can completely solve the problem of scale. The

initial installation cost is higher than that of ordinary water purifiers, but lower than pure water equipment, the cost of consumables used is

lower, and subsequent maintenance is convenient.

In summary, considering the initial installation cost, maintenance cost, and the degree of water purification, water softeners are the preferred

water treatment equipment in general areas.

However, some users have reported that after using the water softener, there will still be scaling. Why? I have to mention the core part of the

water softener-resin.

The working principle of the water softener is to exchange the functional ions on the resin with the calcium and magnesium ions in the water

to achieve the purpose of softening the water. The activity of the resin is the key to soft water. To maintain the activity of the resin, it is necessary

to rely on salt for backwashing. Running the water softener in a salt-deficient state is equivalent to doing useless work. At this time, the water produced

is still hard water, so scale will still appear. When traditional water softeners are short of salt, it is generally impossible to judge from the performance

of the equipment or from the outside. Therefore, many water softeners have been operating under salt shortage for a long time, which not only fails

to achieve the purpose of softening water, but also causes a waste of resources. Hemway's W616 smart water softener solves these problems from

the source.

The W616 water softener is equipped with a salt detection system and has a salt shortage alarm function. When the salt content is less than the

minimum amount, the device will emit a buzzer alarm and the indicator light flashes to remind users to add salt in time to ensure the equipment

Effective operation.

The equipment has multiple filtration systems that can effectively remove sand, colloidal substances and other impurities, deeply purify water quality,

and reduce boiler pipe fouling. Areas with severe water pollution can also be equipped with iron manganese ion scavengers to solve the "yellow water"

phenomenon from irons.

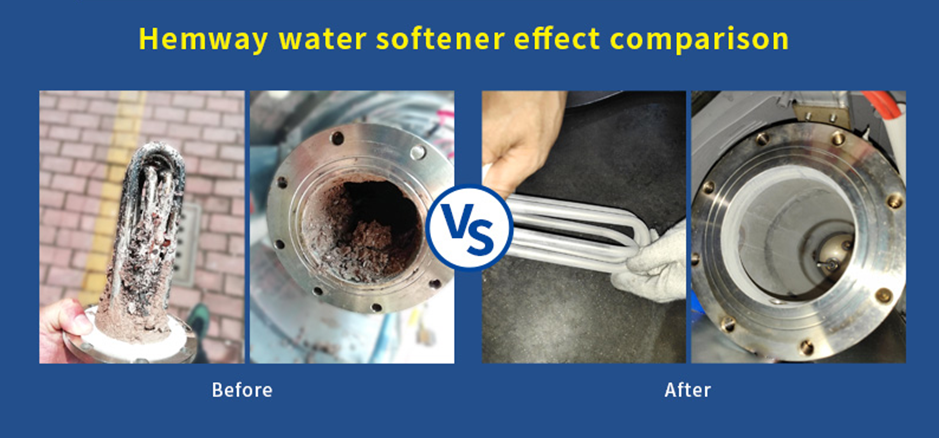

What is the actual effect of W616 water softener? Let's look at a set of comparison charts:

It can be seen that the ironing machine furnace body and heating pipe without a water softener have accumulated and scaled very seriously. As for

the ironing equipment equipped with Hamway water softener, the condition of the inside of the furnace and the heating tube is still very good when

the equipment is maintained after half a year.

A large number of user cases show that in the current situation of increasingly serious environmental pollution and poor water quality, to ensure the

stable operation of ironing equipment, in addition to daily maintenance, the configuration of water softeners is already indispensable.